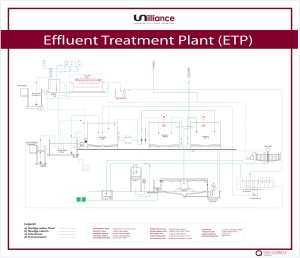

Environment: All process water is treated via a biological plant. From a central drain in the processing shed the process water goes to a balance tank where the biological treatment takes place. The waste water then moves on through a time specific process of aeration, clarification, flocculation and settling which takes place in various tanks on the treatment plant. The final clean water is discharged to the river.

The produced sludge are then taken into filter press machine to drain out the water in it and form as cake.

The plant can process 64 cubic meters of water per hour at capacity.

Apart from complying with number of leading global customer’s Code Of Conduct (COC) audit; we are also audited and awarded certificates like BRC (British Retail Consortium), SEDEX & BSCI for ensuring working & social environment up to the expected level.